Molding

Raw material becomes a finished article.

Our Focus: the ability to transform the raw material into a technical compound with features that meet the needs of our customers.

In order to guarantee a high quality level we are always attentive to training, technological progress, research and development of processes and raw materials.

We listen and understand your needs and, together with you, we develop the right article made with the right material.

Raw material becomes a finished article.

Process to eliminate superfluous raw material residues.

Oven heat treatment to fix the physical and mechanical characteristics of our final articles.

100% sorting is necessary to eliminate final residual and non-standard articles.

The articles are packed and shipped to the end Client.

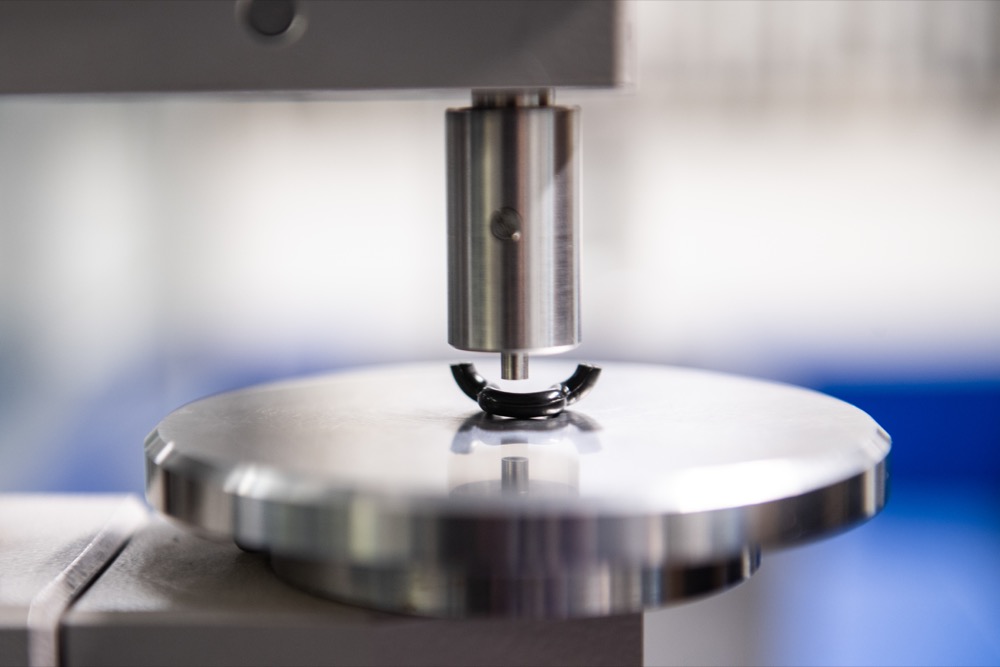

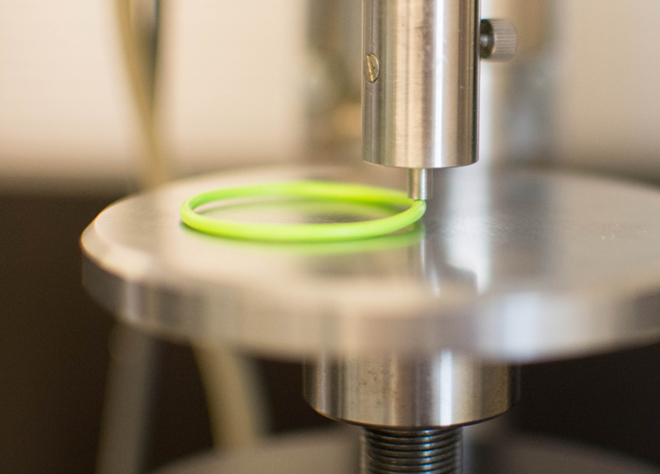

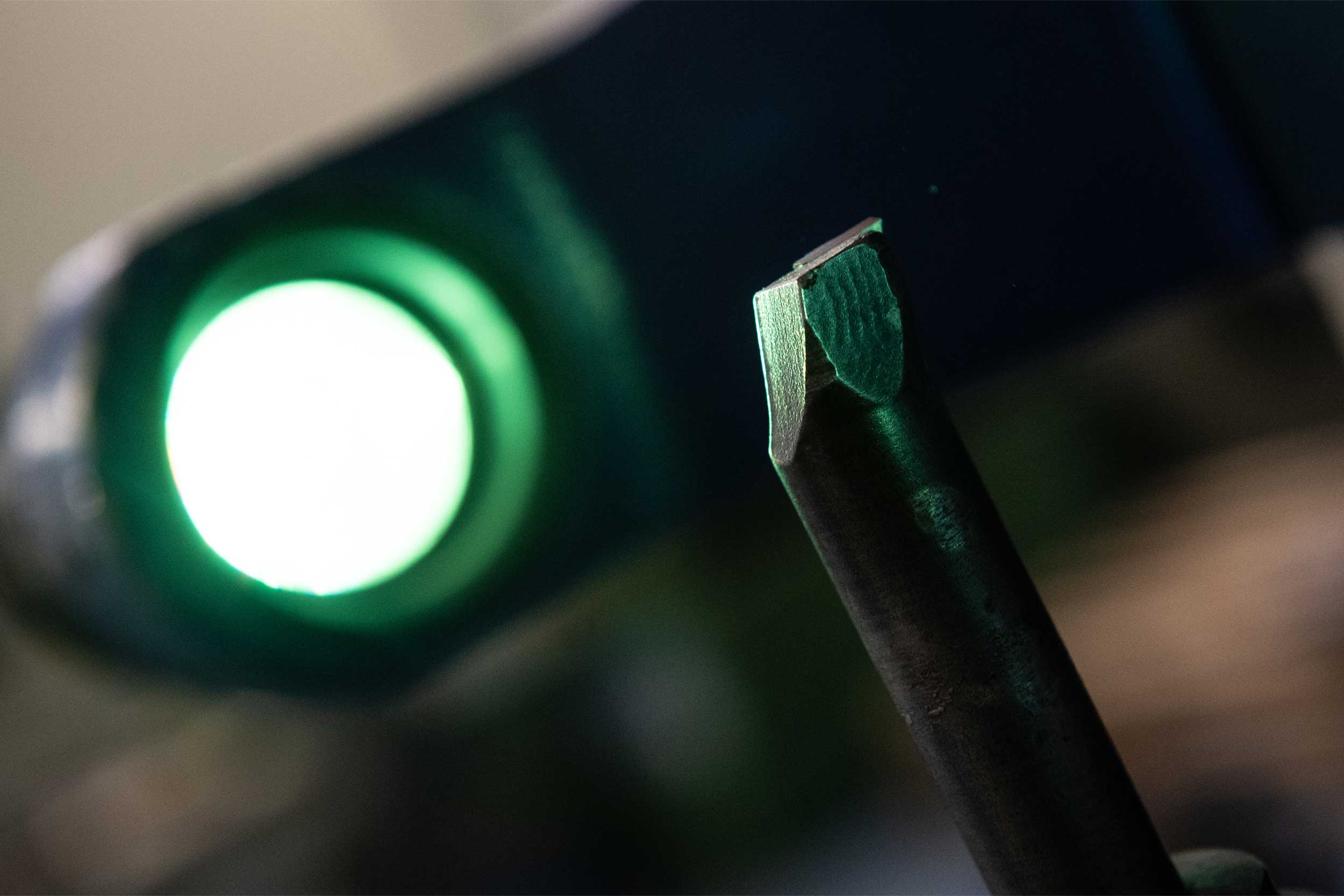

The raw material is the key in ensuring the final product’s quality. In order to assure the highest quality of its products, Italian Gasket only sources its material from certified compound suppliers. Each batch comes with the supplier’s certification ensuring the material’s compliance with the technical specifications. Our in-house laboratory, equipped with the most advanced control systems, guarantees the quality of each batch by performing tests on 100% of the supplies. Main tests and tools available in our test center: Rheometer – Density gauge – TGA (thermal gravimetric analysis) – Durometer – Dynamometer – Ozonometer – TR Test & Brittle Point – Mass comparators – C-Set plates according to ISO 815, ASTM D 395, PV 3307 and PV 3330 – IR (infrared)

IG globally counts 80 machines, including injection molding machines (horizontal and vertical) and compression molding machines with a tonnage between 50 and 680. The molding machines are equipped with the latest automation and temperature control systems ensuring the highest efficiency and interchangeability. Internal deflashing, post-curing and quality control.

Control is the basis of a quality process: constant check of the output through statistical tools and control equipment capable of promptly highlighting anomalies and / or process variation. 100% checks on the finished product and statistical checks before each shipment are an integral part of our production cycle and constitute a further guarantee of a customer-oriented approach.

We will be happy to help.

We will get back to you in max 24 hours.

To contact us, please fill the form, send an e-mail to info@italiangasket.com

or call 035 924511